-

AlexanderGlaubwürdige Lieferanten

AlexanderGlaubwürdige Lieferanten -

LouisEs war mir ein Vergnügen, mit Ihnen zu arbeiten.

LouisEs war mir ein Vergnügen, mit Ihnen zu arbeiten.

Hohe Wärmeeffizienz Horizontale Kessel Ökonomizer mit 1-Jahres-Garantie und Serpentine Tube Design

Kontaktieren Sie mich für kostenlose Proben und Gutscheine.

- Was ist?:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie Bedenken haben, bieten wir 24-Stunden-Online-Hilfe.

x| Typ | Natürliche Zirkulation | Struktur | Wasserröhre |

|---|---|---|---|

| Druck | Hochdruck | Dampferzeugung | Max. 60 t/h |

| Stil | horizontal | Kraftstoff | Kohlenbefeuert |

| Ausgabe | Heißes Wasser | Material | Spezielle Stahlplatte für Kessel |

| Wärmeeffizienz | 92,4 %–94,5 % | Arbeitsdruck | Hochdruck |

| Gewicht | 1-20 Tonnen | Schmelzverfahren | EF+LF + VD |

| Materialstandard | ASTM, EN oder ISO usw. | UT-Standard | ASTM A388 oder EN10228 usw. |

| Verfahren | Material-> INGOT -> HOT/KALD -ROLLING-> WEDERBEHANDLUNG (Normalisierung+ Temperatur) -> | ||

| Hervorheben | Hohe Wärmeeffizienz-Kessel-Ökonomizer,Horizontale Kessel-Ökonomizer,Einjährige Garantie |

||

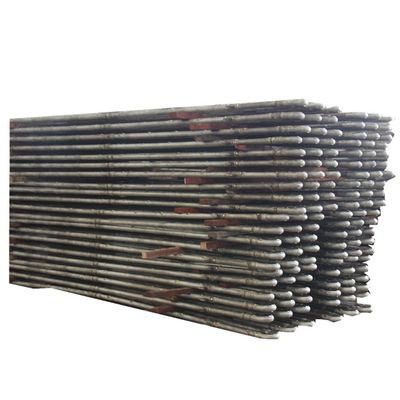

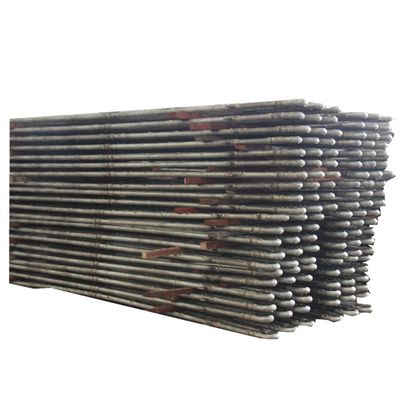

Heizkessel-Ökonomizer sind Wärmeaustauschgeräte mit Flossenröhren, die Flüssigkeiten (typischerweise Wasser) auf Temperaturen unter ihrem Siedepunkt erhitzen.

- mit einer Breite von nicht mehr als 15 mm

- H-Flossen-Rohr-Ökonomizer

- mit einer Breite von mehr als 10 mm

Der H-Finned Tube Economizer ist ein hocheffizienter Wärmetauscher, der aus H-Finned-Röhren besteht.

- Erhöhte Wärmeaustauschfläche

- Verringerte Anzahl der benötigten Schläuche

- Erweiterter Rauchgasflussbereich zur Verringerung der Durchflussgeschwindigkeit und des Abriebs

H-Flossenröhren können als doppelte H-Flossenröhren hergestellt werden, um eine höhere Steifigkeit zu gewährleisten, wodurch sie für lange Rohrreihen geeignet sind.

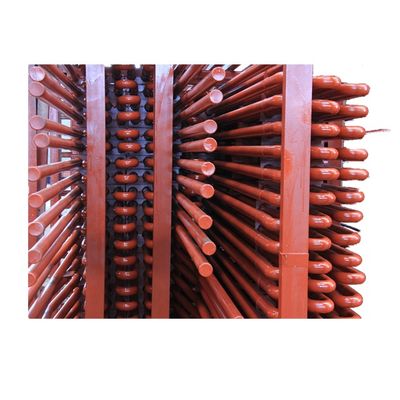

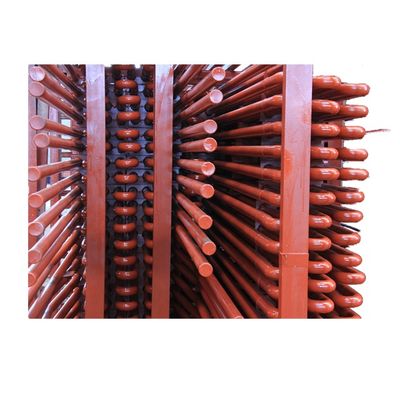

Der Sparer mit Spiralflossen verfügt über ein neues Design mit Spiralflossenröhren, die ernsthafte Abriebprobleme beheben und die Lebensdauer verlängern.

| Beschreibung | Heizkörper |

|---|---|

| Material | Legiertes Stahl, Kohlenstoffstahl, SA210C, SA213T22 usw. |

| Standards für Materialien | ASTM, EN oder ISO usw. |

| Abmessung | Anpassung |

| Gewicht | Min: 10 Tonnen Höchstmenge: 1000 t |

| Schmelzverfahren | EF+LF + VD |

| Verfahren | Material→Ingot→Hot/Cold-Rolling→Wärmebehandlung (Normalisierung+Tempering)→Inspektion→Rohbearbeitung→UT→zweite Wärmebehandlung→Bearbeitung bis zur Veredelung→Inspektion |

| UT-Standard | ASTM A388 oder EN10228 usw. |

- Aufprallprüfung und Bericht über die Festigkeitsberechnung mit Angaben zu den verwendeten Materialien

- 100% NDT-Bericht (nicht zerstörerischer Überprüfung) von Stahlplatten, Rohren und Elektroden

- Röntgen-, γ- und Flüssigkeitsdurchdringungstestbericht (Schweißnaht) zur Gewährleistung der Qualität des Kessels

- Hydraulischer Prüfbericht zur Überprüfung des Arbeitsdrucks und der Sicherheit