-

AlexanderGlaubwürdige Lieferanten

AlexanderGlaubwürdige Lieferanten -

LouisEs war mir ein Vergnügen, mit Ihnen zu arbeiten.

LouisEs war mir ein Vergnügen, mit Ihnen zu arbeiten.

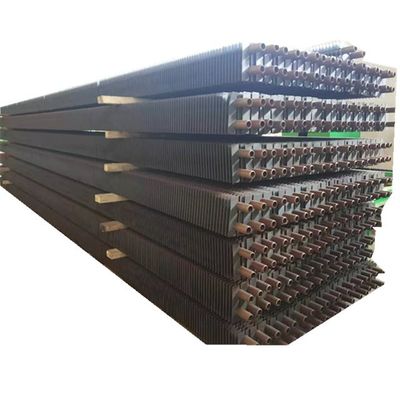

H Fin Tube Economizer mit maximal 20 t/h Dampferzeugung 1 Jahr Garantie und 5 Jahre Kernkomponenten Garantie

Kontaktieren Sie mich für kostenlose Proben und Gutscheine.

- Was ist?:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie Bedenken haben, bieten wir 24-Stunden-Online-Hilfe.

x| Typ | Natürliche Zirkulation | Struktur | Feuerrohr und Wasserrohr |

|---|---|---|---|

| Druck | Niedrig/Hochdruck | Dampferzeugung | Max. 20 t/h |

| Stil | Vertikal | Kraftstoff | Kohle / Gas / Kohle / Wasserspeise |

| Ausgabe | Heißwasser/Dampf | Oberflächenbehandlung | Gestrichen |

| Material | Legierungsstahl, Kohlenstoffstahl, SA210C, SA213T22 | Materialstandard | ASTM, EN oder ISO |

| Gewichtsbereich | 10 Tonnen - 1000 Tonne | Schmelzverfahren | EF+LF + VD |

| Verfahren | Material-> INGOT-> HOT/KALD-ROLLING-> WEDERBEHANDLUNG-> Inspektion-> Rauhbearbeitung- | UT-Standard | ASTM A388 oder EN10228 |

| Wärmetauschertyp | H-Finned Tube Economizer | ||

| Hervorheben | Maximal 20 t/h Dampferzeugung H Fin Tube Economizer,1 Jahr Garantie H Fin Tube Ökonomizer,5 Jahre Kernkomponenten Garantie H Fin Tube Ökonomizer |

||

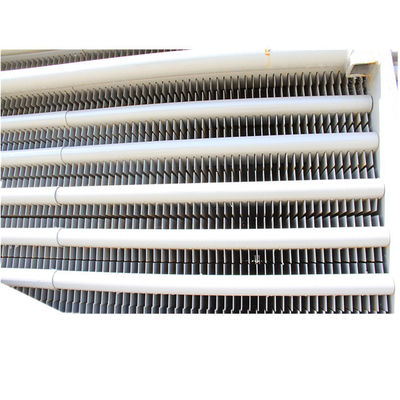

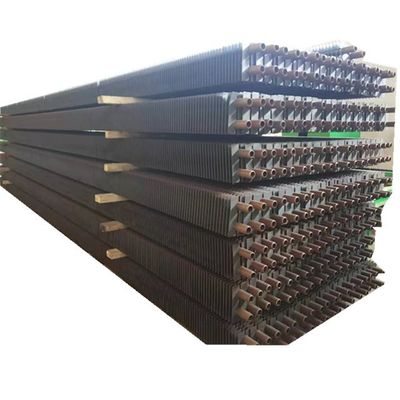

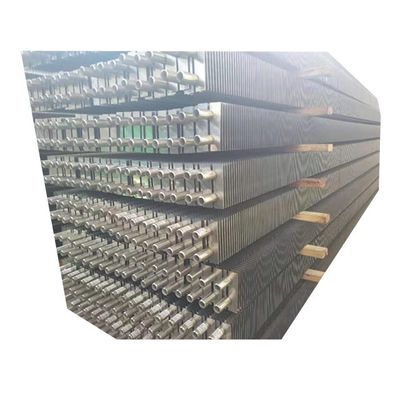

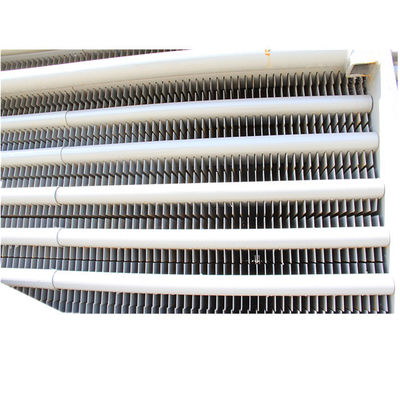

Heizkörper sind hocheffiziente Wärmeaustauschgeräte mit Flossenröhren, die dazu bestimmt sind, Flüssigkeiten (typischerweise Wasser) zu erhitzen, ohne dass sie ihren Siedepunkt erreichen.Wir produzieren drei Arten von Heizkessel-Ökonomisatoren:

- mit einer Breite von nicht mehr als 15 mm

- H-Rohr-Ökonomizer mit Flossen

- mit einer Breite von mehr als 10 mm

- Vergrößert den Wärmeaustauschbereich und reduziert gleichzeitig die Anzahl der erforderlichen Rohre

- Erhöht den Abgasflussbereich, um die Durchflussgeschwindigkeit und den Abrieb zu reduzieren

- Erhältlich in der Doppel-H-Finnen-Rohrkonfiguration für eine erhöhte Steifigkeit in langen Rohrreihen

- Leistungs- und Haltbarkeitsqualität überlegen

Der Ökonomizer reduziert die Kühlkosten erheblich, indem er die Wärmeübertragungseffizienz optimiert und Kompressor-Auslösungen ermöglicht, während eine ausreichende Kühlkapazität beibehalten wird.

| Beschreibung | Heizkörper |

|---|---|

| Material | Stahllegierung, Kohlenstoffstahl, SA210C, SA213T22 |

| Standards für Materialien | ASTM, EN oder ISO |

| Abmessung | Anpassbar |

| Gewicht | 10 bis 1000 Tonnen |

| Schmelzverfahren | Der Wert der Verringerung wird durch die Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung der Verringerung. |

| Herstellungsprozess | Material→Ingot→Hot/Cold-Rolling→Wärmebehandlung→Inspektion→Rohbearbeitung→UT→zweite Wärmebehandlung→Bearbeitung bis zum Abschluss→Endkontrolle |

| UT-Standard | ASTM A388 oder EN10228 |

- Aufprallprüfungs- und Festigkeitsberechnungsberichte mit Materialinformationen

- 100% NDT (nicht zerstörerischer Test) von Stahlplatten, Rohren und Elektroden

- Röntgen-, γ- und Flüssigkeitsdurchdringungstests für alle Schweißschichten

- Hydraulische Prüfberichte zur Überprüfung des Arbeitsdrucks und der Sicherheitsstandards